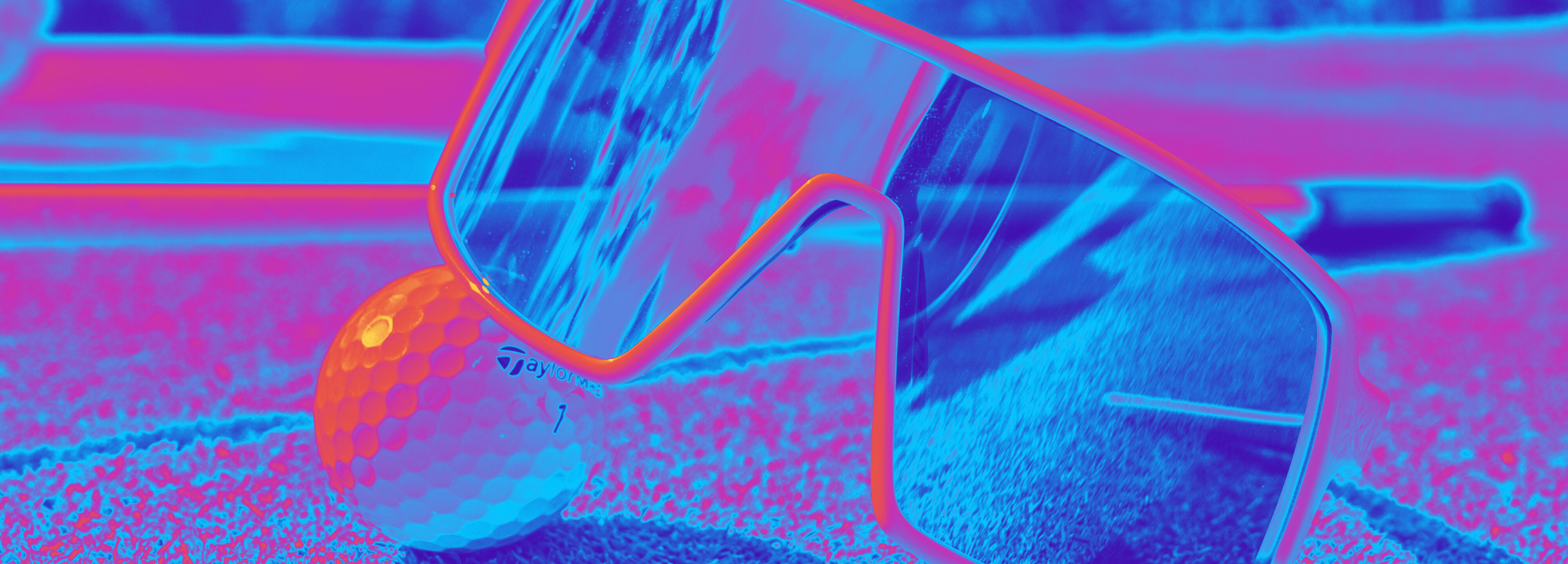

Sharper clarity.

Reliable protection.

Lens: Rose with External Blue Iridium

Lens: Grey with External Red Iridium

Lens: Grey

Lens: Rose with External Blue Iridium

Lens: Rose with External Blue Iridium

The difference

Imagine the difference between watching a game on a regular TV and then switching to HD. Both give you the full picture, but HD makes everything sharper, colours brighter, and details stand out more clearly.

HIgh definition Range

Stay sharp in the field with Carve’s Elite Performance eyewear. Featuring High-Definition Nylon lenses with Iridium coating, these lenses enhance contrast, cut glare, and deliver crisp vision in variable light—helping you track the ball with precision every moment.

standard range

Featuring Iridium-coated lenses, Velocity reduces harsh sunlight and glare, boosts contrast, and keeps your vision crisp in bright conditions. As part of Carve’s standard performance range, it offers stability and impact resistance for reliable eye protection—helping athletes stay focused and perform at their peak.

#Shoppink

Supporting the McGrath Foundation

For every pair of Carve Pink Performance sunnies sold, we donate $10 to the McGrath Foundation. It’s our way of turning style into support—helping fund breast care nurses across Australia while you look good, feel good, and make a difference with every wear.